技术数据

碳钢物理性能

耐腐蚀性能

Early fasteners relied on applying a thin layer of .00015 inch to .0005 inch of Electro-deposited zinc plating with .0003 being the norm. This was done in order to prolong the fastener life and to improve the appearance. A considerable number of years ago, Atlas pioneered the introduction and use of the Mechanical-Zinc plating process, which eliminates Hydrogen-embrittlement in the manufacturing process. One more advantage is the increased thickness range of deposited zinc ranging from .0003 inch to .001 inch, with .0005 being the norm.

Prior to plating, all carbon steel fasteners are case-hardened to create a hard surface for drilling and tapping while maintaining a softer core for ductility. Parts can also have added corrosion protection, by optionally coating fasteners with Oxyseal long life coating, either alone or in conjunction with a conventional paint finish that substantially increases the life of the fastener.

金属成分

C .20-.25 Mn .80-1.10 P .040 S .050

410不锈钢物理性能

耐腐蚀性能

Stainless Type 410, in both annealed and heat-treated conditions, provides good corrosion resistance to mild atmospheres. It resists corrosion in many light industrial and domestic environments as well as potable and mine waters.

The alloy has acceptable resistance to sulfide stress cracking at Rockwell C 22 maximum hardness per NACE MR-01-75, "Sulfide-Stress-Cracking-Resistant Metallic Materials for Oil Field Equipment." Refer to the current document for details on acceptable conditions.

For optimum corrosion resistance, surfaces must be free of scale and foreign particles and finished parts should be passivated.

金属成分

C .15 Mn 1.00 P .040 S .030 Si 1.00 Cr 11.5 - 13.5

304不锈钢物理性能

耐腐蚀性能

Annealed Project 70 stainless Type 304 is resistant to atmospheric corrosion, foodstuffs, sterilizing solutions, many organic chemicals and dyestuffs, and a wide variety of inorganic chemicals.

Intergranular corrosion may be a problem if the material is heated between 800F (427C) and 1650F and (899C) or cooled slowly through that range.

For optimum corrosion resistance, surfaces must be free of scale and foreign particles and finished parts should be passivated.

金属成分

C .08 Mn 2.00 P .045 S .030 Si 1.00 Cr 18.0 - 20.0 Ni 8.0 - 10.5

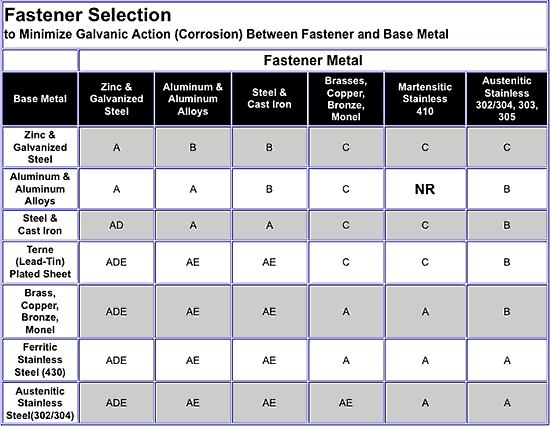

Fastener Selection

To minimize Galvanic Action (Corrosion) Between Fastener and Base Metal

KEY A - corrosion of the base metal is not increased by the fastener B - corrosion of the base metal is marginally increased by the fastener C - corrosion of the base metal may be markedly increased by the fastener D - plating on the fastener is rapidly consumed, leaving the bare fastener metal E - corrosion of the fastener is increased by the base metal NR - not recommended Note: Surface treatment and environment can change activity.